View:11 Date:2023-01-05

On January 4, 2023, the company held the 2022 Safety Production Work Summary and 2023 Safety Production Work Deployment Meeting via video link connecting conference rooms in Beijing and Anshan, as well as all project sites. The meeting was chaired by Yang Zhiwei, head manager of environment, health and safety department. Attendees include company executives, heads of various departments, project managers, all staff of the environment, health and safety department, and safety management engineers from each project site.

Beijing and Anshan Conference Room

At the meeting, the EHS Department presented a summary of the work in 2022. Under the correct guidance of the Safety Committee, the department overcame difficulties characterized by “two multiples and one wide scope” (multiple simultaneous construction projects—22 project sites operating at the same time; large number of project participants—reaching 2,018 personnel; wide geographical distribution—from the coastal areas of Vietnam to the icy northern regions). Adhering to the principle that “safety production is everyone’s responsibility,” the department established and improved the safety production responsibility system, weaving a three-dimensional “protective network” formed by project managers, construction managers, and safety management engineers. This achieved the “dual-zero target” (zero severe injuries and zero fatalities). Through system development and strengthened safety education, safety awareness was raised at all levels. Safety Production Month activities in June and Fire Safety Month activities in November were actively carried out, along with various emergency drills, embedding safety awareness deeply into everyone’s mindset. Throughout the year, strengthened safety supervision over project sites and increased efforts in identifying potential hazards yielded certain results. No severe injury or fatal accidents occurred, meeting the safety production goals set at the beginning of the year. For 2023, the company’s safety target remains the “dual-zero” goal for severe and fatal accidents. The EHS Department has laid out specific plans and deployments for this year’s safety production work.

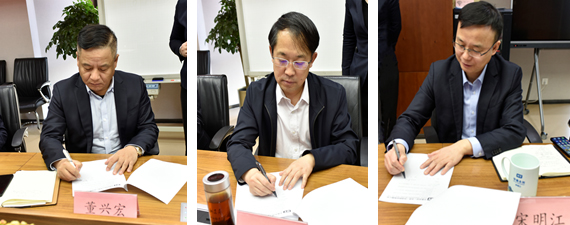

The General Manager signed the 2023 Safety Production Target Responsibility Documents with Deputy General Managers, heads of departments, and project managers.

The General Manager signs safety production target responsibility documents with Deputy General Managers

Deputy General Manager Dong Xinghong emphasized the importance of safety production work at the meeting. He stated that relying solely on the supervision and management of the EHS Department is far from sufficient. Everyone must earnestly assume their safety responsibilities and act as the first person responsible for safety. Deputy General Manager Dong stressed that project managers must report safety conditions truthfully; any false reporting or concealment will be strictly penalized.

Deputy General Manager Song Mingjiang acknowledged the achievement of the annual safety production targets in 2022. Through the year’s efforts, the safety awareness of key management personnel has improved, shifting from “safety imposed on me” to “I want safety.” Deputy General Manager Song sets higher requirements for safety management: First, strengthen hazard identification to prevent safety incidents from the source. Second, safety production management is a systematic project, not limited to safety alone. It must be implemented comprehensively across design, procurement, and construction management, with each department fulfilling its responsibilities. The design institute must achieve intrinsic safety through design, the material and equipment procurement department must procure qualified products, and the site must be meticulously organized—only then can intrinsic safety be realized.

At the end, General Manager Han Dong delivered an important speech. He first advised talking less about achievements and focusing more on identifying gaps. Although the “dual-zero” target was achieved in 2022, three minor injury incidents and three near-miss incidents occurred, serving as a wake-up call. Vigilance in safety production work must never relax. We must uphold the principle of “life first, safety first,” persistently and consistently implementing all safety production tasks. Second, safety management must follow the “three- izations” path: institutionalization, standardization, and proceduralization. The supervision and accountability mechanisms must be continuously improved. Departments, project sites, or individuals engaging in formalism or lax implementation of systems will be held accountable to prevent “systems on the wall” from becoming mere “wall decorations.” DuPont’s safety management philosophy states that all safety accidents are preventable. We firmly believe our company can achieve this as well.

Life is priceless, but safety neglect reduces all to zero. For the happiness of our loved ones and for a better tomorrow, let us join hands with safety to create a harmonious and bright future together.